Zhou Youhe, a professor from the College of Civil Engineering and Mechanics of Lanzhou University, independently completed a research paper on 3D green printing ultra-light high-temperature YBCO superconducting bulk materials with the title "Efficient fabrication of ultralight YBA2Cu3O7x superconductors with programmable shape and structur" E "was published in the internationally renowned journal Advanced Functional Materials (IF: 16.836). Professor Zhou Youhe and Professor Zhang Xingyi are co-communicators, and the first author is Zhang Baoqiang, a doctoral student of Zhou Youhe; Professor Zhang Qiangqiang and his master's student He Peng, Professor Zhou Youhe's other doctoral student Ma Yanbin and Zhang Xingyi's doctoral student Shen Lei are the other authors. This paper is another breakthrough in the modification and preparation of superconducting materials after Zhou You and his research team successfully prepared high-performance joint materials with the lowest electrical resistance and the highest mechanical strength.

According to the reviewer of this paper, "the authors present a clever way to 3d print a green body of yba2cu3o7 super conductor ceramic that has many technological and industrial pot." ntial. It is a well structured article, which presents the preparation of the paste and the 3D printing process in detail. The results indicate that the YBCO 3D printed bodies have good magn etic properties and the videos are extremely elucidative regarding the properties” “The prepared 3D printed YBCO samples are multi-scale and multi-leve l porous structures with improved Jc and crystallinity, especially for the Jc, which was approximately 3.15 times higher than that of the traditional cold-press sintering samples. The authors demonstrated the production of a holl ow flywheel structure for a gyroscope, which was used as a navigation aid in the space industry. The developed printed structure has complex fine properties, flexibility, is ecological and highly efficient.”

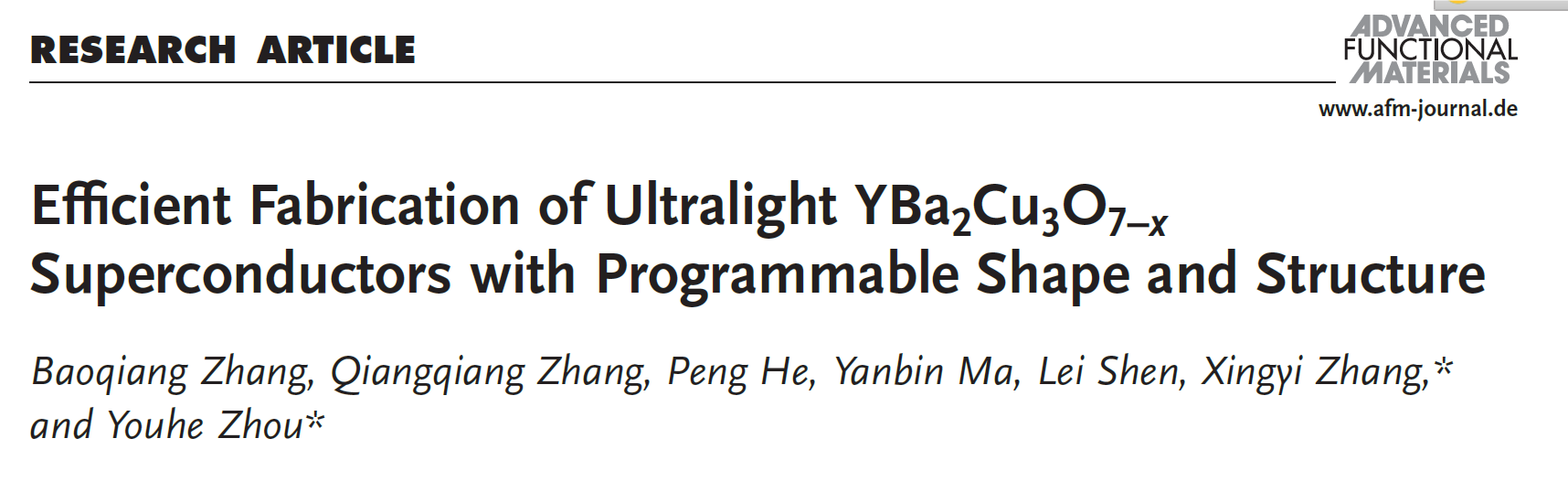

High-temperature superconducting YBCO blocks have a wide application prospect in the development of new high-performance devices and electromagnetic devices such as contactless magnetic levitation, energy storage rotating machinery, quasi-permanent magnets, sound mixers, magnetic lenses, portable medical devices, filters, aerospace navigation gyroscopes, etc. due to their excellent performance of high critical temperature, high critical current density and high trapping magnetic field. Especially for the research and development of rotating machinery, space navigation gyro and portable medical devices, the preparation of light superconducting materials on the premise of keeping superconductivity is a main goal pursued by such applications. The research of this paper originated from the exchange meeting of three innovative research groups of National Foundation of Solid Mechanics held in Zhejiang University in 2015. At this exchange meeting, Academician Yang Wei, then director of the Fund Committee, pointed out that the inherent brittleness of superconducting materials greatly restricted the mechanical properties of superconducting applications, and there was a big contradiction between superconductivity and mechanical properties. It was suggested that Lanzhou University should tackle key problems with toughening modification. Subsequently, under the guidance of Professor Zhou Youhe, Professor Zhang Xingyi and others carried out basic exploration work on sintering preparation, nano-pinning and crystal orientation control of YBCO bulk materials. Five years ago, Professor Zhang Qiangqiang received his Ph.D. from Harbin Institute of Technology and was selected to work in the College of Civil Engineering and Mechanics of Lanzhou University. He is mainly engaged in 3D printing preparation and performance characterization of graphene materials, and has achieved remarkable results. With the support of the college, Zhang Qiangqiang built a preparation platform for 3D printing. Subsequently, Zhou Youhe proposed to Zhang Xingyi and Zhang Qiangqiang that toughening superconducting materials should be listed as the demand and possible realization of expanding research on this platform. Under the guidance of Professor Zhou Youhe, after two years of exploring and tackling key problems, a green and environmentally-friendly high-precision direct writing (DIW)3D printing method for YBCO superconducting materials was put forward, which solved the problems of slurry ratio and rheological control of non-Newtonian fluid ceramics. Then, a low-temperature cold casting microstructure control strategy was adopted, which solved the problem of sintering shrinkage cracking of superconducting bulk materials and realized the efficient and controllable preparation of complex multi-scale and multi-level ultra-light superconducting bulk materials. The preparation process is shown in Figure 1. Through performance characterization, the process parameters with the best performance are obtained.

Fig. 1. Schematic diagram of preparation process of green superconducting YBCO block

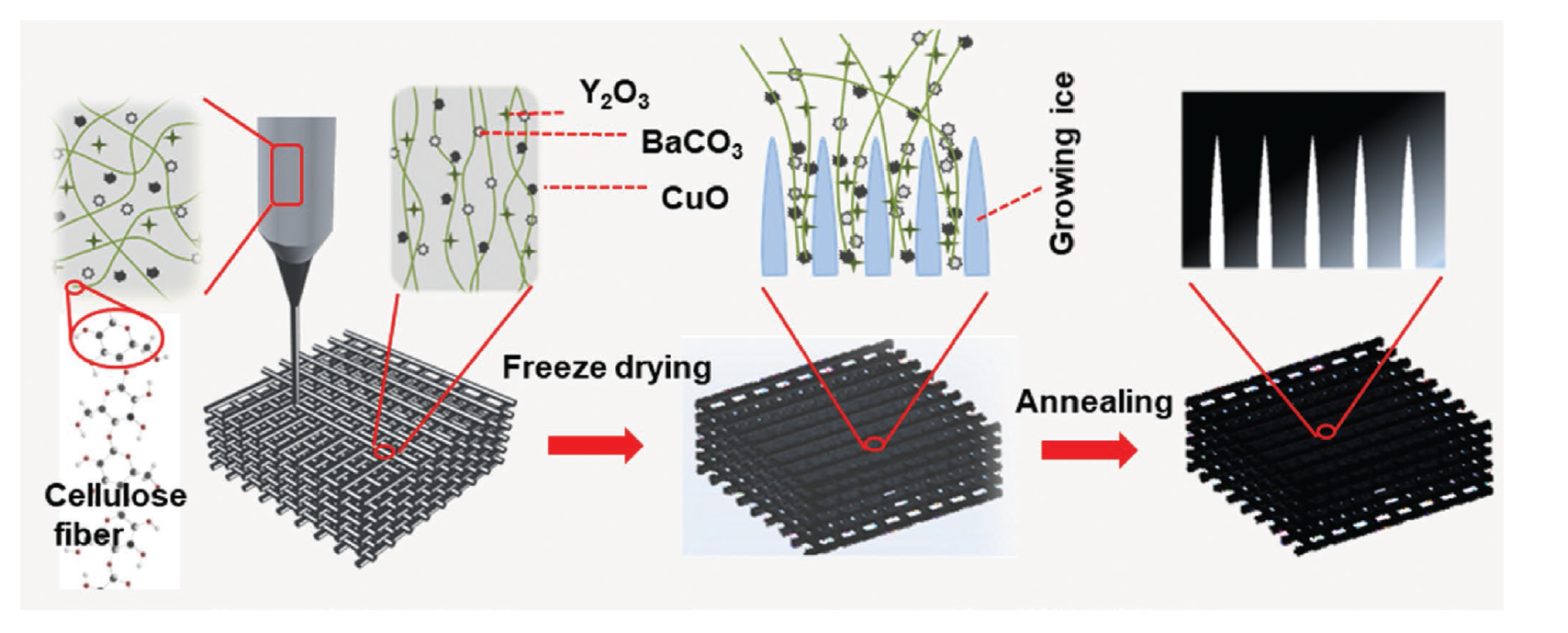

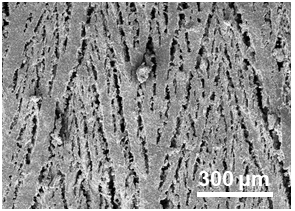

The green slurry produced with the help of edible organic materials in this new process shows excellent rheological properties of DIW, and realizes the preparation of YBCO block with refined and complex controllable structure (see Figure 2). In order to solve the problem of high shrinkage (up to 50%) faced by existing 3D printing ceramic materials, the low-temperature cold casting strategy was proposed, which achieved high shape retention of 3D printing superconducting materials (see Figure 3), and laid a foundation for high-precision preparation of YBCO superconducting bulk materials. At the same time, the sintering time and oxygen supplement time of this new process are greatly shortened compared with the traditional process, and the preparation efficiency of superconducting materials is improved. The mass density of YBCO block with 3D porous, multi-scale and multi-layer configuration prepared in this paper is only 1.38 g per cubic centimeter, which is the lowest in the world at present and about 1/3 of the samples prepared by traditional cold pressing sintering process. The critical current density is about 3.15 times higher than that of the samples prepared by traditional sintering method (as mentioned in the previous review comments).

?

Figure 2. YBCO sample preparedFigure 3. YBCO sample after cold casting at low temperature

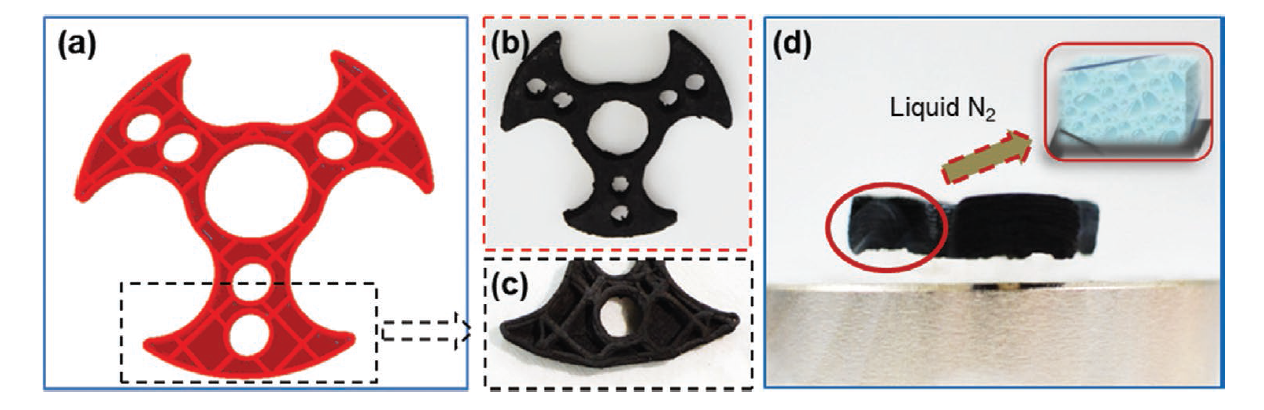

This process has the advantage of being convenient for industrial preparation and application, and then the structural form expected by engineering or R&D departments can be prepared. For example, it is difficult to realize the macro YBCO micro-rotating gyroscope structure needed for space navigation by traditional process, but the process in this paper is easy to prepare, and its performance is not changed by the change of shape. Fig. 4 shows that YBCO samples with a diameter of about 40mm are produced by 3D printing based on CAD design configuration, which realizes the floating characteristics of navigation gyro.

The 3D printing preparation technology of YBCO superconducting bulk materials proposed in this paper lays a foundation for the 3D printing preparation of other superconducting materials that need toughening modification in the future, and Zhou Youhe's team is doing research on process improvement and preparation.

Fig. 4. (a) CAD design of perforated structure configuration according to the suspension function requirements of space navigation gyro; (b) YBCO superconducting flywheel samples prepared by 3D printing method; (d) a video screenshot of the YBCO superconducting flywheel sample suspended above a permanent magnet in liquid nitrogen

Website of thesis connection:https://doi.org/10.1002/adfm.202100680